Ever wondered how much a PET plastic sheet really costs? It’s not just about thickness or size—many hidden factors matter. PET plastic sheets are clear, strong, and widely used in packaging, displays, and machinery. Knowing their price helps avoid overpaying or choosing the wrong type.

In this post, you’ll learn what affects PET sheet pricing, key types, and how pet sheet suppliers like HSQY can help.

What is PET Plastic Sheet Made Of?

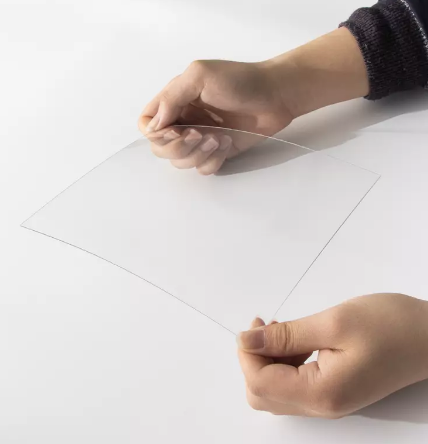

PET plastic sheet comes from a material called polyethylene terephthalate. It’s one of the most common thermoplastics we see every day. You’ll find it in bottles, containers, and even clothing fibers when it’s used as polyester. But when made into a sheet, it becomes a clear, strong material perfect for packaging and industrial use.

Physically, PET sheet is lightweight but tough. Its density is about 1.38 grams per cubic centimeter, which helps make it durable without being heavy. Thermally, it handles temperatures up to 170 degrees Celsius, though its working range is often lower in daily use. Mechanically, it’s stiff and resistant to breaking, which is why many industries pick it over glass or acrylic.

PET sheet also stands out in how it performs under pressure. It has high tensile strength, so it won’t tear easily during shaping or transport. This makes it useful for things like forming trays or printing clear display covers. Even under heat, it stays stable enough for thermoforming, letting people mold it into packaging, inserts, or cosmetic boxes without much trouble.

![PET&PETG plastic sheet PET&PETG plastic sheet]()

Thanks to these properties, PET sheet shows up everywhere. Packaging is a major use, especially for food and electronics. It’s common in clear window boxes, plastic cartons, and blister packs. Thermoforming uses it to shape items like storage trays or lids. In printing, it gives clean results with excellent clarity. You’ll also see it in automotive panels and advertising signs, where strength and looks both matter.

This flexibility is what makes PET plastic sheet a favorite among pet sheet suppliers. They rely on it to serve many markets—from industrial users to retail brands needing sharp, clear packaging.

How is the Price of PET Plastic Sheet Calculated?

Density and Grammage Calculations

To estimate PET plastic sheet cost, we first look at its density. It stays steady at around 1.38 grams per cubic centimeter. When you multiply this by the sheet's area and thickness, you get the grammage, or how many grams each square meter weighs. This makes it easier to calculate costs per square meter when using bulk raw material prices.

For example, a 0.1mm thick PET sheet has a grammage close to 138 gsm. If you double the thickness to 0.2mm, it becomes about 276 gsm. The calculation looks like this: Thickness (in mm) × 1000 × 1.38 = gsm. Once you get the gsm, you can estimate price using the market rate for PET, often based on cost per ton.

Let’s say raw PET costs around RMB 14,800 per ton. You divide the gsm by 1,000,000, multiply by the ton price, and that gives you the price per square meter. So a 138 gsm PET clear sheet would cost about RMB 2 per square meter in raw form.

Price Benchmarks (Theoretical vs Practical)

That sounds simple in theory, but real-world pricing includes more than just material weight. Processing steps like extrusion, cutting, protective films, or anti-static coatings raise the actual cost. Packaging, freight, and supplier margins also count.

Take 0.2mm PET as an example. Its raw material cost might start at just $0.6 per square meter. But once it's cut, cleaned, and packed, the price often climbs to around $1.2 per square meter. That's what you’ll see in quotes from experienced pet sheet suppliers.

Actual prices differ by region and platform. On Taobao, for instance, 100 large sheets of PET with protective films might sell for around RMB 750. On TradeIndia, listed rates range from INR 50 to INR 180 per sheet or roll, depending on the features. In Germany, retail prices for PETG sheets can start at about €10.5 per square meter, but go up with UV protection or special thicknesses.

So while it’s easy to do the math using gsm, buyers need to factor in real-world extras. Understanding both the baseline and added costs helps you better plan your next PET plastic sheet order.

What Factors Affect the Cost of PET Plastic Sheets?

Thickness and Size

The thicker the PET plastic sheet, the more it costs per square meter. That’s because thicker sheets use more raw material and take longer to cool during processing. A 0.2mm sheet may cost under $1.50 per square meter, but a 10mm sheet can be over €200 per square meter in some European markets. Size also plays a role. Large full-size sheets cost more overall, but less per square meter compared to small custom cuts. Cut-to-size sheets usually add labor and handling costs, while rolls are cheaper if bought in bulk.

Quantity and Order Volume

When buyers place small orders, they pay higher rates per unit. That’s normal. But once the quantity increases, most pet sheet suppliers apply tiered pricing. For example, a single catering tray made of rPET may cost €0.40, but that price drops if someone orders multiple cases. Whether you're ordering 10 sheets or 1000 rolls, volume discounts make a big difference. Wholesale buyers also skip retail margins, which lowers their cost further.

Processing Requirements

Extra features make PET sheets more useful, but also more expensive. Want UV protection for outdoor use? That can triple the price per square meter compared to indoor sheets. Anti-fog coatings, anti-static treatments, or full-color printing all add cost. Even CNC-cutting or die punching adds labor time. Some suppliers include up to 10 straight cuts for free, but advanced processing might cost over €120 per hour, depending on the region.

PET vs APET vs PETG vs RPET: Which One Affects Price?

Understanding the Types

There’s more than one kind of PET used in plastic sheets, and each type comes with different features and costs. APET stands for amorphous polyethylene terephthalate. It’s the most rigid and offers the clearest visual appearance. That’s why people use it in packaging for cosmetics, electronics, or printed displays where glass-like clarity matters.

PETG, on the other hand, is a modified version that includes glycol. It doesn’t crystallize like APET does. That makes it easier to thermoform or bend without stress marks. You’ll often see it used in machine guards or credit cards, where durability and formability are key. PETG has great impact resistance, but it melts at a lower temperature, usually around 70 to 80 degrees Celsius.

Then there’s RPET, or recycled PET. It’s made from post-consumer or industrial PET waste, like used bottles. It can be a mix of colors or grades, so clarity might not be perfect. Still, RPET is a solid choice for industrial trays or packaging where looks aren't the priority. It’s also eco-friendly and often cheaper than virgin materials.

Price Hierarchy

If we look at average market pricing, PETG usually costs the most. Its added glycol and flexibility make processing easier but more expensive. APET comes next. It costs less than PETG but still more than recycled options, especially when high clarity or food safety is required. RPET is generally the most affordable, though high-quality food-grade RPET can sometimes rival or exceed APET pricing due to limited supply.

That said, prices aren’t fixed. They shift based on grade, origin, and feedstock quality. In some regions, APET might actually cost more than PETG, especially when clarity and chemical resistance are in high demand. So it really depends on the use case and supplier.

Best Use Scenarios

Need sharp clarity for a printed insert or cosmetic box? APET is your go-to. It holds its shape well, looks clean, and resists heat better than PETG. For applications that involve bending or require shatter resistance—think safety covers or display parts—PETG works better. It bends cold and won’t crack like APET under stress.

If you're buying in bulk for industrial sorting trays or low-cost packaging, RPET is a smart move. It’s widely available and sustainable. Just check the specs carefully, since color and quality can vary more than virgin materials.

HSQY PLASTIC GROUP: Reliable PET Sheet Supplier

Introducing Our PET & PETG Plastic Sheets

At HSQY PLASTIC GROUP, we’ve spent over 20 years perfecting how PET and PETG plastic sheets are made. Our factory runs five advanced production lines and pushes out around 50 tons every single day. That allows us to meet global demand without cutting corners on quality.

One of our flagship products is PETG film, also known as GPET. It’s a non-crystalline copolyester built using CHDM, which gives it different traits than traditional PET. You’ll find it easy to form, smooth to bond, and resistant to common cracks or whitening.

![the PET plastic sheet the PET plastic sheet]()

We offer multiple formats based on what clients need. Rolls range from 110mm to 1280mm in width. Flat sheets come in standard sizes like 915 by 1220mm or 1000 by 2000mm. If you need something in between, we can customize that too. Thickness ranges from 1mm to 7mm. Both transparent and colored versions are available.

Here’s a quick look at the core specs:

| Format | Size Range | Thickness | Color Options |

| Roll | 110–1280 mm | 1–7 mm | Transparent or Colored |

| Sheet | 915×1220 mm / 1000×2000 mm | 1–7 mm | Transparent or Colored |

Key Features

What sets our PETG sheet apart is how well it performs under real-world conditions. You don’t need to pre-dry it before shaping, which saves time and energy. The toughness is hard to beat—our sheets are up to 20 times stronger than regular acrylic and up to 10 times tougher than impact-modified acrylic.

They hold up well outdoors too. PETG resists weather damage and yellowing, even after long UV exposure. For design flexibility, the material is easy to saw, cut, drill, or even cold-bend without breaking. If needed, the surface can also be flocked, printed, coated, or electroplated. It bonds smoothly and stays clear, which makes it ideal for a wide range of commercial uses.

And yes—it’s fully food-safe and meets FDA standards. That makes it a safe choice for packaging and display work, especially where clarity and hygiene are a priority.

Product Applications

Because it’s strong, clear, and flexible, our PET and PETG sheets get used in many places. You’ll see them in signage, both indoors and outdoors. Many vending machines, retail racks, and display cases rely on them for visibility and durability. Builders use our sheets for construction barriers and protective panels.

Our materials also go into mechanical baffles and industrial safety covers. One special use is in credit cards—Visa itself approved PETG as a base material thanks to its flexibility, toughness, and environmental benefits. It’s also a great match for packaging in electronics, cosmetics, and household goods.

Why Choose HSQY as Your PET Sheet Supplier?

Customers around the world choose us because we care about more than just selling plastic. We focus on product quality, delivery speed, and long-term partnerships. Our team supports sustainability and safe manufacturing practices. If your business needs technical help or special designs, we’ll guide you through it.

We don’t just meet industry standards—we help set them. Our customization service lets you create what fits your exact needs. And because we produce in volume, we can offer competitive pricing that works for small buyers and bulk importers alike.

How to Compare Prices from Different PET Sheet Suppliers

Tips on Requesting Quotes

When you’re ready to get pricing from a PET sheet supplier, be clear about what you need. Don’t just ask for a general PET plastic sheet. Instead, include the thickness, sheet size, and material type—whether it's APET, PETG, or RPET. If you're ordering rolls, mention the width range. For sheets, confirm the length and width. Also, say if the material is for food contact or outdoor use. That tells the supplier if it needs to be food-safe or UV-resistant. The more details you give, the more accurate the quote will be.

Here’s a quick list of what to include:

Thickness (in mm)

Format (roll or sheet)

Dimensions

Material type (PET, PETG, RPET)

Usage (food packaging, printing, signage, etc.)

Required certifications (FDA, EU, etc.)

Volume or estimated order size

How to Evaluate Price vs Quality

A low price can look attractive, but it doesn’t always mean a good deal. Some sheets may be cheaper because they lack clarity, have weak impact strength, or come from low-grade recycled content. Others might skip coatings that prevent yellowing or scratches. You’ll want to check the physical samples if possible. Hold the sheet under light to judge its clarity. Bend it gently to feel its toughness.

Ask yourself:

Is the material clear or hazy?

Does it resist cracking or whitening when bent?

Can it handle heat or UV if needed?

Some sellers provide technical datasheets. Use those to compare values like tensile strength, melting point, or impact resistance. If you're printing or thermoforming, make sure the material supports that process. Ask for a trial piece if your application is sensitive.

Understanding Supplier Certifications and Traceability

This part matters most for food, cosmetics, or medical packaging. If the product touches anything people eat or apply, you need traceable materials. That means buying from suppliers who can prove where their resin comes from. Some suppliers offer virgin PET only, especially for pharma and food sectors. Others mix in recycled content—great for cost and sustainability, but only if properly sorted and cleaned.

Check if the supplier holds certifications like:

FDA food-contact approval

EU Regulation EC No. 1935/2004

ISO 9001 for quality systems

REACH and RoHS compliance

If you’re ordering RPET, ask whether it's post-consumer or post-industrial. High-end food-grade RPET can be more expensive than virgin PET due to strict processing steps. Suppliers should give you a declaration of compliance or test reports. If they don’t, that’s a red flag.

Reliable pet sheet suppliers won’t just give you a price—they’ll explain what’s behind it. And that’s what helps you make the right call.

PET Plastic Sheet vs Other Materials: Is It Cost-Effective?

PET vs PVC

Both PET and PVC are used in packaging, signage, and display applications, but they behave differently. PET tends to be more transparent, so it's preferred when people want that crystal-clear look. PVC, while strong, often has a slight blue tint. That may not matter for industrial use, but it does for retail displays or food windows.

Recyclability is another key point. PET is widely recycled and accepted in most recycling systems. PVC, on the other hand, is harder to recycle and may release harmful gases if burned. Some regions even restrict its use in food contact products due to health concerns over chlorine-based compounds. PET has FDA and EU food contact approvals, making it safer and more versatile in packaging.

In terms of price, PVC can be more stable because it uses less oil in its production. But overall, PET is often cheaper by about 20 percent when comparing similar sheet formats. Especially when bought in bulk, PET offers better value for high-clarity, food-safe uses.

PET vs Polycarbonate

Now let’s look at PET and polycarbonate. Polycarbonate is extremely tough—it can take impacts that would crack or dent PET. That’s why it’s often used in safety equipment, helmets, or bullet-resistant glass. But that toughness comes at a price. Polycarbonate is more expensive, heavier, and harder to print on.

PET still has good strength, especially PETG, which handles stress well. It’s also lighter, easier to cut, and works well for thermoforming. PET doesn’t need pre-drying like polycarbonate does, which saves time and energy during manufacturing. For most retail, packaging, or signage applications, PET delivers enough strength at a much lower cost.

If you’re printing labels, folding boxes, or forming trays, PET gives you smoother print results and better flexibility in shape. So unless you're dealing with extreme environments or need advanced impact resistance, polycarbonate is often overkill.

When PET is the Most Economical Choice

PET plastic sheet becomes the best-value option when you need a balance of clarity, strength, and price. It works great in food packaging, retail boxes, cosmetic trays, and thermoformed displays. When compared to other plastics, it often delivers more features at a lower cost per square meter.

It’s also safer for long-term use. PET doesn’t release harmful fumes during processing like PVC sometimes does. It’s easier to recycle, safer for food contact, and strong enough for most general applications. If your project doesn't need extreme toughness or specialty coatings, PET sheet is probably your smartest, most cost-effective choice.

Conclusion

PET plastic sheet pricing changes based on many factors.

Thickness, type, and processing all affect the final cost.

Material choice also depends on how it will be used.

You’ll need to consider clarity, flexibility, and certifications.

A trusted supplier like HSQY can guide you through each option.

For reliable quotes, contact a professional pet sheet supplier today.

FAQs

What is the average cost of PET plastic sheet per square meter?

Depending on thickness and processing, it ranges from about $0.6 to $1.2 per m².

Is PETG more expensive than regular PET or APET?

Yes. PETG typically costs more due to its flexibility and easier forming.

Can PET plastic sheets be used for food packaging?

Absolutely. PET and PETG are both food-safe and FDA-approved for direct contact.

Why do prices differ between suppliers?

It depends on order size, material quality, processing, and regional market rates.

Where can I buy custom PET sheets in bulk?

Contact HSQY PLASTIC GROUP. They offer custom sizes, global shipping, and competitive pricing.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu