Have you ever wondered how to cut PVC board effectively? This versatile material is used in various applications, from construction to furniture design.

In this article, we’ll explore what PVC board is, its types, and why it’s a popular choice. You’ll learn the best methods for cutting PVC board and tips for achieving clean edges.

Introduction to PVC Board

What is PVC Board?

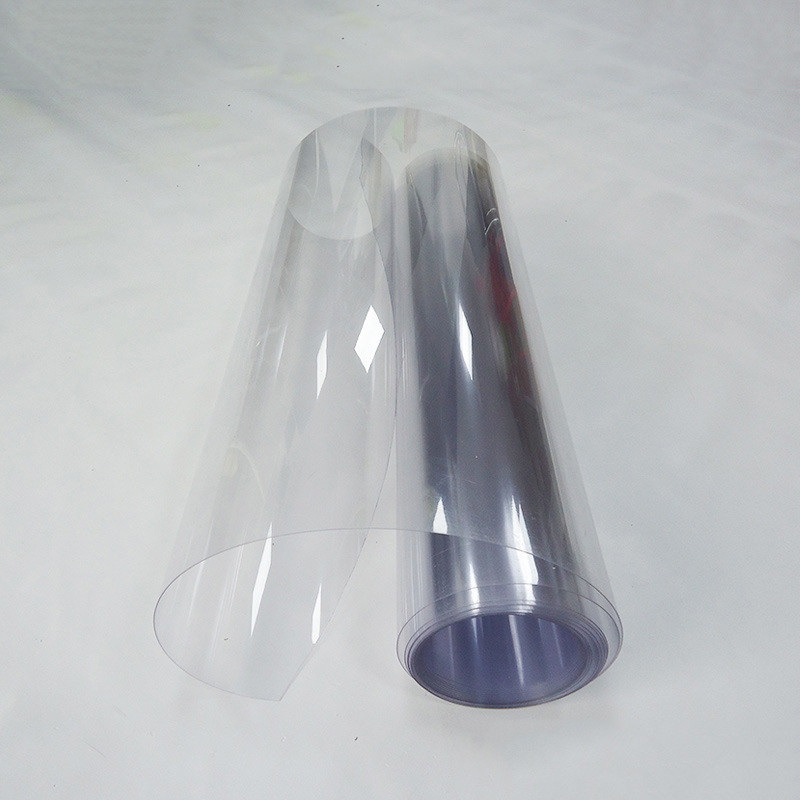

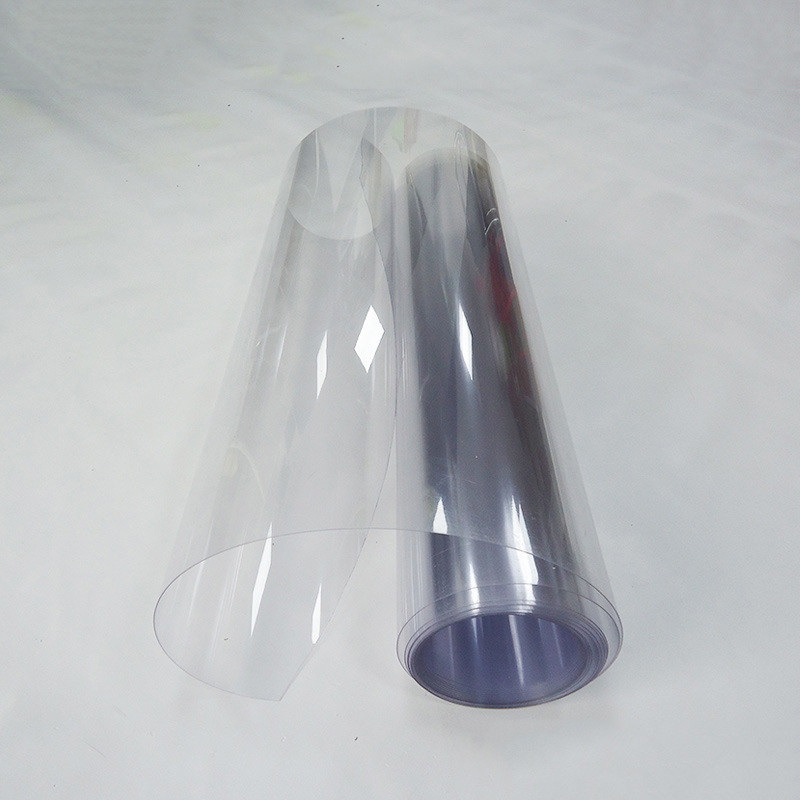

PVC board, or polyvinyl chloride board, is a versatile material made from a synthetic plastic polymer. Its composition includes a mix of vinyl and other additives, making it strong and durable. This type of board is available in various forms, each tailored for specific uses.

Types of PVC Boards

There are three main types of PVC boards:

● Rigid PVC Board: Stiff and strong, ideal for structural applications.

● Flexible PVC Board: More pliable, perfect for projects requiring bending or shaping.

● Expanded PVC Board: Lightweight and easy to cut, commonly used in signage and displays.

Why Use PVC Board?

PVC board is a popular choice for many reasons. First, it offers durability and weather resistance, making it suitable for both indoor and outdoor applications. Its versatility allows it to be used in a range of industries, including:

● Construction: Used for wall panels, ceilings, and plumbing.

● Advertising: Ideal for signs and promotional displays.

● Furniture Design: Perfect for creating custom furniture pieces.

Comparison with Competitor Products

When comparing PVC board to other materials, it stands out for several reasons.

Advantages Over Wood-Based Products

● Moisture Resistance: Unlike wood, PVC doesn’t warp or rot when exposed to moisture.

● Low Maintenance: It requires minimal upkeep, saving time and effort.

Advantages Over Metal Products

● Lightweight: PVC is much lighter than metal, making it easier to handle and install.

● Cost-Effectiveness: Generally, it’s less expensive than metal, reducing overall project costs.

Advantages Over Other Plastic Products

● Cost-Effectiveness: PVC board is often cheaper than other plastics, providing great value.

● Chemical Resistance: It withstands exposure to various chemicals, making it suitable for industrial applications.

Common Applications

PVC board is widely utilized across different sectors. Here are some common applications:

● Construction: Used for window frames, doors, and cladding.

● Advertising: Perfect for billboards and point-of-sale displays.

● Furniture Design: Employed in making cabinets, tables, and shelves.

In summary, PVC board is a robust and adaptable material. Its unique properties and advantages make it an excellent choice for a variety of projects, from construction to creative design.

Tools and Materials Needed for Cutting PVC Board

Cutting PVC board requires specific tools and safety gear to ensure efficiency and safety. Here’s a breakdown of what you need.

Essential Tools

1. Utility Knife

The utility knife is a go-to tool for cutting PVC board, especially for thinner sheets.

Best Practices:

a. Use a fresh blade for clean cuts.

b. Score the surface several times before snapping it along the line.

c. Always cut on a stable surface to avoid accidents.

2. Circular Saw

A circular saw is perfect for larger sheets of PVC board.

When to Use It:

a. For straight cuts on thicker boards.

b. Safety Tips:Always use a blade designed for plastic.

c. Keep hands clear of the cutting path.

3. Jigsaw

The jigsaw is great for making intricate cuts and curves.

Advantages:

a. It allows for detailed work and can navigate tight corners.

b. Use fine-toothed blades for best results.

4. Table Saw

a. This tool is ideal for cutting large sheets quickly and accurately.It provides straight, even cuts, making it efficient for big projects.

b. Ensure the board is securely held down during cuts.

5. Scoring Tool

A scoring tool is handy for making straight cuts on thinner PVC sheets.

How It Works:

a. Simply score the surface along the desired line, then snap the board along the score.

b. It’s perfect for quick, clean cuts without needing power tools.

Safety Gear

Safety should always come first when cutting PVC board. Here are essential items to consider:

● Protective Eyewear: Always wear safety glasses to protect your eyes from flying debris.

● Gloves: Use cut-resistant gloves to prevent injuries while handling sharp edges.

● Dust Mask: A dust mask is recommended to avoid inhaling fine particles. This is especially important when using power tools.

Safety Gear | Purpose |

Protective Eyewear | Protects eyes from debris |

Gloves | Prevents cuts and abrasions |

Dust Mask | Reduces inhalation of harmful particles |

By having the right tools and safety gear, you can cut PVC board effectively and safely. Make sure to prepare your workspace and gather everything needed before starting your project.

Preparing to Cut PVC Board

Before diving into cutting PVC board, it’s crucial to prepare properly. This ensures clean cuts and a smoother process. Here’s what you need to know.

Choosing the Right PVC Board

When selecting PVC board, consider these factors:

● Thickness: Thicker boards are sturdier but harder to cut. For detailed work, thinner boards might be better.

● Type: Different types (rigid, flexible, expanded) serve various purposes. Choose based on your project needs.

● Intended Use: Think about where the board will be used. Outdoor applications may require UV-resistant options.

Measuring and Marking

Accurate measurements lead to precise cuts. Here’s how to do it right:

1. Measure Carefully: Use a tape measure to get the exact length and width you need.

2. Mark the Cutting Line: Use a straight edge and a pencil for clear visibility.

3. Tips for Straight Cuts:Always double-check measurements before cutting.

a. Consider using a square to ensure your lines are perfectly straight.

Setting Up Your Workspace

The workspace plays a vital role in cutting PVC board effectively. Here’s how to set it up:

● Stable Surface: Ensure your cutting surface is flat and secure. A workbench or sawhorses can help.

● Indoor vs. Outdoor Cutting:Indoor: Choose a well-lit area with minimal distractions.

○ Outdoor: Ensure you have a level ground and protection from wind, which can affect precision.

Workspace Setup | Recommendations |

Stable Surface | Use a workbench or sawhorses for stability |

Indoor Cutting | Well-lit, quiet area for focus |

Outdoor Cutting | Level ground, protected from wind |

By choosing the right PVC board, measuring accurately, and setting up a proper workspace, you’ll be well-prepared for cutting. This preparation makes the cutting process smoother and more efficient.

Step-by-Step Guide on How to Cut PVC Board

Cutting PVC board can be straightforward if you follow the right steps. Here’s a detailed guide covering various methods to help you achieve the best results.

Cutting with a Utility Knife

Using a utility knife is a simple and effective way to cut PVC board, especially for thinner sheets.

Detailed Steps for Scoring and Snapping

1. Measure and Mark: Use a straight edge to mark your cutting line clearly.

2. Score the Line: Firmly run the utility knife along the marked line, applying consistent pressure. Score multiple times for deeper cuts.

3. Snap the Board: Place the scored line over the edge of a table. Press down firmly to snap it along the score.

Tips for Achieving Clean Edges

● Always use a sharp blade to prevent jagged edges.

● Score multiple times if the board is thick to ensure a clean break.

Using a Circular Saw

A circular saw is great for larger sheets and thicker boards.

Setting Up the Saw: Blade Selection and Adjustments

● Blade Selection: Use a fine-toothed blade designed for plastics.

● Adjustments: Set the saw to the correct depth to avoid cutting too deep into your work surface.

Step-by-Step Cutting Process

1. Secure the Board: Clamp it down to prevent movement.

2. Align the Saw: Position the saw blade along the marked line.

3. Cut Slowly: Move the saw steadily along the line for a clean cut.

Cutting with a Jigsaw

A jigsaw is perfect for intricate designs and curves.

Best Practices for Using a Jigsaw on PVC

● Blade Type: Use a fine-toothed blade for smoother cuts.

● Speed Settings: Adjust the speed to a lower setting for better control.

Tips for Intricate Designs and Curves

● Draw the Design: Clearly mark your cutting lines.

● Go Slow: Take your time to navigate curves and corners for accuracy.

Using a Table Saw

This tool is ideal for making straight cuts on large sheets.

Setting Up for Straight Cuts

1. Adjust the Fence: Set the fence according to your desired width.

2. Check Blade Height: Ensure the blade height is appropriate for the thickness of the board.

Safety Precautions and Techniques

● Always wear safety goggles and gloves.

● Keep hands away from the blade and use push sticks for added safety.

Scoring and Snapping Method

This method is efficient for thinner boards.

How to Score Correctly

● Use a straight edge to guide your knife.

● Score deeply enough to weaken the material but not through completely.

Techniques for Snapping the Board Cleanly

● Support the board on both sides of the score.

● Apply even pressure to snap it along the scored line.

Method | Best For | Key Tip |

Utility Knife | Thinner sheets | Score multiple times |

Circular Saw | Large, thick sheets | Use a fine-toothed blade |

Jigsaw | Intricate designs | Go slow and steady |

Table Saw | Straight cuts | Use push sticks for safety |

Scoring and Snapping | Quick cuts on thin boards | Score deeply, then snap |

By following these steps, you can effectively cut PVC board using various methods. Choose the one that best suits your project needs.

Post-Cutting Considerations

After cutting your PVC board, there are a few important steps to take to ensure your project looks great and is safe to handle. Let’s explore the key post-cutting considerations.

Finishing Edges

Once you’ve cut the board, it’s essential to finish the edges for a polished look.

Sanding Techniques for Smooth Edges

● Choose the Right Grit: Start with a coarse grit (around 80) to remove rough edges, then progress to a finer grit (220) for a smooth finish.

● Sand in One Direction: Always sand along the edge rather than in circles. This prevents scratches and achieves a cleaner look.

● Use a Sanding Block: This helps maintain even pressure and prevents uneven sanding.

Options for Sealing or Finishing the Cut Edges

● PVC Edge Banding: Consider applying edge banding for a professional finish.

● Sealants: Use a PVC-compatible sealant to protect the edges from moisture and wear.

● Paint or Coating: If desired, apply paint or a protective coating to enhance appearance and durability.

Cleaning Up

Proper cleanup is crucial after cutting PVC board to maintain safety and organization.

Best Practices for Disposing of PVC Waste

● Collect Scraps: Gather all PVC scraps and waste materials in a designated bag or container.

● Check Local Regulations: Some areas have specific guidelines for disposing of PVC. Always follow local regulations for disposal.

● Recycling Options: If possible, explore recycling options for PVC materials to minimize waste.

Cleaning Tools and Workspace After Cutting

● Clean Your Tools: Wipe down saw blades and cutting tools to remove any PVC residue. This prolongs their lifespan.

● Sweep the Workspace: Use a broom or vacuum to clean up dust and small pieces. A tidy workspace is safer and more efficient.

● Store Materials Properly: Return unused PVC boards and tools to their designated storage areas to keep everything organized.

Task | Best Practice |

Sanding Edges | Use a sanding block for even pressure |

Sealing Edges | Apply edge banding or sealants |

Disposing of Waste | Follow local regulations for PVC disposal |

Cleaning Tools | Wipe down tools to remove residue |

Cleaning Workspace | Sweep or vacuum to maintain safety |

By paying attention to these post-cutting considerations, you can enhance the quality of your work and maintain a safe, organized environment.

![Rigid 3mm transparent PVC sheet Rigid 3mm transparent PVC sheet]()

Common Mistakes to Avoid When Cutting PVC Board

Cutting PVC board can be a straightforward task, but several common mistakes can lead to frustration and poor results. Let’s dive into the pitfalls to avoid.

Improper Measurements

One of the biggest errors people make is not measuring accurately.

Consequences of Inaccurate Cuts

● Wasted Material: Incorrect measurements often result in wasted boards, leading to increased costs.

● Fit Issues: If cuts are off, pieces may not fit together as intended, causing delays and extra work.

● Frustration: Repeatedly making inaccurate cuts can be frustrating and demotivating.

Tip: Always double-check measurements before cutting. Use a reliable measuring tool, like a tape measure or a square.

Using Dull Tools

Dull tools can significantly impact your cutting experience.

How Dull Blades Affect the Cutting Process

● Rough Edges: Dull blades tend to tear the material instead of cutting cleanly, resulting in jagged edges.

● Increased Effort: You’ll need to apply more pressure, which can lead to fatigue and less control.

● Safety Risks: Using dull tools increases the risk of slips or accidents, as they can bind and kick back unexpectedly.

Tip: Regularly inspect and sharpen or replace blades to ensure smooth cuts.

Neglecting Safety Precautions

Safety should always be a priority when working with tools.

Importance of Safety Gear and Workspace Organization

● Wear Protective Gear: Always use safety goggles and gloves to protect against flying debris and sharp edges.

● Organize Your Workspace: Keep tools and materials organized to minimize tripping hazards and distractions.

● Avoid Loose Clothing: Ensure clothing is fitted to prevent it from getting caught in tools.

Mistake | Consequence | Prevention Tip |

Improper Measurements | Wasted material and fit issues | Double-check measurements |

Using Dull Tools | Rough edges and increased effort | Regularly sharpen or replace blades |

Neglecting Safety Precautions | Increased risk of accidents | Always wear safety gear and stay organized |

By avoiding these common mistakes, you can enhance your cutting experience and achieve better results when working with PVC board.

FAQ

Q: Can you cut PVC board with regular saws?

A: Yes, PVC board can be cut using regular saws like circular saws, jigsaws, or hand saws. Ensure the blade is suitable for plastic to achieve clean cuts.

Q: What is the best method for cutting thick PVC boards?

A: For thick PVC boards, a table saw or a circular saw with a fine-toothed blade is recommended. These tools provide better control and cleaner cuts.

Q: How do you achieve a smooth finish on cut PVC edges?

A: To achieve a smooth finish, sand the edges with progressively finer grits and consider applying edge banding or a sealant for added protection.

Q: What are the properties of PVC boards that influence cutting methods?

A: PVC boards are corrosion-resistant, durable, provide good insulation, and have flame resistance, which affects the choice of cutting tools and techniques.

Conclusion

Cutting PVC board requires the right tools and techniques.

Choosing suitable saws and methods is crucial for clean cuts.

Don't hesitate to experiment with different approaches.

We invite you to try cutting PVC board for your projects.

Share your experiences or ask questions in the comments below!

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu