Is PVC stronger than PS? Is PS clearer than PVC? These two plastic sheets look similar, but they perform very differently. PVC is tougher. PS is lighter.

In this post, you'll learn how to compare them for packaging, construction, and more.

What is PVC Plastic?

PVC stands for polyvinyl chloride. It’s one of the most widely used plastic materials in the world. You’ll often find it in plumbing pipes, window frames, cable insulation, and even medical tubing. What makes it popular is its strength and versatility. It holds up well against impact, moisture, and many chemicals.

It’s also naturally flame-retardant. That means it doesn’t catch fire easily, which is why builders like using it for siding and wires. People choose PVC because it’s affordable and performs reliably in lots of environments.

There are two main types of PVC. One is flexible, also called plasticized PVC. This version gets softened by adding plasticizers, so it's easier to bend. It works well for hoses or cable coatings. The other kind is rigid. It’s known as uPVC or unplasticized PVC. It’s stiffer and stronger, making it ideal for pipes and structural parts.

Engineers have also developed special versions like CPVC and PVC-O. CPVC can handle hot water better and is used in home plumbing systems. PVC-O has extra strength from how it’s processed, so it’s great for high-pressure piping.

Here’s a quick look at how the types compare:

| Type | Flexibility | Common Uses | Notes |

| PVC-U | Rigid | Pipes, window frames | High strength and durability |

| PVC-P | Flexible | Cable insulation, tubing | Softened with plasticizers |

| CPVC | Rigid | Hot water pipes | Better temperature tolerance |

| PVC-O | Rigid | Pressure pipes | Lightweight, impact-resistant |

PVC has been around since the early 1900s. It’s a tough, lightweight plastic that can be shaped, colored, and customized in many ways. That's why it remains so popular across different industries today.

What is PS Plastic?

PS, or polystyrene, is a type of plastic that feels light but stays rigid. You’ll often see it used in everyday disposable items like food trays, forks, spoons, and those clear plastic cups at parties. It’s popular because it’s cheap to produce and easy to shape through molding. That’s why it shows up in everything from packaging foam to CD and DVD cases.

This material has a smooth surface and good clarity, especially in its solid form. It’s often made into transparent or colored sheets, called PS sheets. People use them in signs, food containers, display windows, and advertising boards. Since it insulates electricity well, you might also find it used in electronic parts.

But polystyrene doesn’t hold up well under impact. If you drop it, it may crack or shatter. Unlike PVC, which resists fire, PS is known to catch fire easily. In fact, when used in buildings, it has to be covered behind walls or concrete to meet safety rules.

Polystyrene comes in a few types, including foam and solid forms. Here’s a comparison:

| Type | Appearance | Common Uses | Notes |

| General PS | Clear or colored | CD cases, cutlery | Rigid and brittle |

| HIPS | Opaque | Toys, appliances | Impact-resistant |

| EPS (foam) | White, light | Packaging, insulation | Expanded for cushioning |

It’s been around since the 1930s and remains a favorite in the packaging world. Just keep in mind that although it’s recyclable, many places don’t recycle it due to its low density. When not managed properly, foam PS can end up polluting land and water.

PVC vs PS Plastic: What Are the Key Differences?

PVC and PS might look similar in clear sheets, but they act very differently in real use. PVC holds up better when it comes to impact or pressure. It’s stronger and more flexible, which makes it a good choice for construction and plumbing. People use it in places where strength, weather resistance, and safety matter more.

PS is lighter, more rigid, and easier to mold into specific shapes. You’ll see it in disposable packaging and thin display windows. It’s clear and neat but not made for tough jobs. If it gets hit or dropped, it may crack. Unlike PVC, it doesn't do well with heat either. PS starts to change or break down even before it reaches high temperatures.

They also differ in how they handle the sun or chemicals. PVC can resist many acids, salts, and oils. It even holds up better in drain pipes and outdoor use. PS handles light chemicals but doesn’t last as long, especially if left in direct sunlight.

Now let’s look at them side by side:

| Feature | PVC Plastic Sheet | PS Plastic Sheet |

| Density | 1.3 – 1.45 g/cm³ | 1.04 – 1.06 g/cm³ |

| Strength & Toughness | High | Low |

| Flexibility | Moderate | Low |

| UV Resistance | Low | Low |

| Chemical Resistance | Excellent | Moderate |

| Heat Resistance | Up to 60°C (PVC), 90°C (CPVC) | Starts decomposing at lower temps |

| Flammability | Flame-retardant | Highly flammable |

| Applications | Pipes, cladding, signage | Packaging, insulation, displays |

PVC fits heavy-use or permanent jobs. PS fits best where looks, clarity, and low cost come first.

Which Plastic is Better for Packaging? PS vs PVC

When it comes to packaging, both PS and PVC sheets have their place. But they don’t perform the same. If you're packaging something light and disposable like food or snacks, PS sheet might be the better pick. It’s clear, stiff, and easy to shape. That’s why it’s used so often for lids, trays, and clear windows on snack boxes.

PS looks neat and gives a clean display. It makes your product stand out without adding weight. Stores like it because it helps customers see the item right away. But there’s a trade-off. PS doesn’t handle impact well and may crack during transport. Plus, it won’t protect much against moisture or dust.

PVC sheet, especially transparent PVC, works better when the goal is to protect the product. It’s more flexible than PS, so it bends without breaking. It also blocks water, dust, and air better. This makes it perfect for packaging that needs to stay sealed or clean, like electronics, cosmetics, or health products.

Here's how they compare side by side:

| Property | PS Sheet | PVC Sheet |

| Clarity | Very high | High |

| Strength | Low | Moderate to high |

| Flexibility | Low | Moderate |

| Moisture Protection | Poor | Good |

| Ideal Use | Display trays, food containers | Clear boxes, sealed packaging |

So if your product needs to look sharp on a shelf, PS might be the way to go. But if it needs to stay clean, dry, or protected during shipping, PVC makes more sense.

Is PVC More Heat-Resistant Than PS?

At first glance, PS seems like the winner when it comes to heat. Its melting point is around 240°C, much higher than regular PVC. But there's a catch. Even before it melts, PS starts to break down or deform at lower temperatures. That makes it a bit risky for anything exposed to steady heat or warm environments.

PVC, on the other hand, stays more stable under moderate heat. Standard PVC can handle up to about 60°C before it begins to soften. That’s not very high, but it’s predictable and safe for everyday use like drainage or insulation.

When we step into higher-temperature jobs, there’s CPVC. This version of PVC goes through a special process to handle heat better. It performs well up to 93°C and sometimes more. That’s why people use it in hot water systems, especially in home plumbing. It resists softening, stays strong, and doesn’t release harmful fumes as quickly as PS.

Here’s a quick look at how they compare:

| Material | Melting Point | Practical Heat Tolerance | Suitable Applications |

| PS | Around 240°C | Decomposes below 100°C | Trays, display boxes |

| PVC | 75–105°C | Up to 60°C | Cold water pipes, signage |

| CPVC | 90–110°C | Up to 93°C | Hot water pipes, indoor plumbing |

So while PS technically melts at a higher temp, it doesn’t always survive the heat. PVC, especially CPVC, handles real-world heat better.

Environmental Impact: PVC vs PS Sheet

When we talk about plastic, people often ask which one harms the planet more. Both PVC and PS come with challenges, but in different ways. PVC is recyclable, and new recycling methods are improving. Still, if it’s burned, it can release chlorine gas. That’s dangerous for both air and human health. It also takes a long time to break down, so it needs to be handled properly.

PS sheet is recyclable too, but it’s not always easy to process. Its light weight and foam forms make it hard to collect and clean. If it gets dirty, most recycling plants won’t accept it. As a result, a lot of PS ends up in landfills or oceans. Foam waste like Styrofoam is one of the top plastic pollutants found along coastlines.

Some businesses now look for greener solutions. Bio-based PVC and high-recovery plastic sheet materials are becoming more common. These materials keep the benefits of plastic but lower the damage to the environment.

| Factor | PVC Sheet | PS Sheet |

| Recyclability | Moderate | Low |

| Burning Risk | Releases chlorine gas | Emits soot and carbon |

| Marine Pollution Risk | Low (if handled) | High, especially foam types |

| Bioplastic Options | Available (bio-PVC) | Limited |

| Common Disposal Issue | Burning, landfill | Littering, floating waste |

We all play a role in reducing plastic waste. Choosing recyclable or less harmful materials helps more than people think.

Common Applications of PVC and PS Sheets

PVC and PS sheets serve different industries, but they both show up in products we see every day. PVC is strong, weather-resistant, and holds up under stress. That’s why it’s common in construction, healthcare, and even outdoor spaces. We use it for pipes, tubing, fencing, and transparent panels in packaging. It also works well in electrical systems since it insulates cables and wires.

PS, in contrast, is light and easy to shape. It’s ideal for short-term, low-impact items. People often choose PS when they need clear containers or lightweight displays. Think of fast food trays, plastic cutlery, or those clear cases that hold CDs and DVDs. It also gets used a lot in creative spaces like signs, craft projects, and protective screens.

There are some of the most common uses:

| PVC Sheet Uses | PS Sheet Uses |

| Pipes and fittings | Disposable food containers |

| Medical tubing | CD cases, DVD packaging |

| Decking and fencing | Advertising boards, signage |

| Transparent window packaging | Acrylic-like plastic tableware |

| Electrical cable insulation | DIY crafts and protective screens |

Each material has its own strengths, so they show up in places where those strengths matter most. Some jobs need flexibility and chemical resistance. Others just need something clear and light.

HSQY PLASTIC GROUP: PS and PVC Sheet Solutions

At HSQY PLASTIC GROUP, we produce reliable PS and PVC sheets for packaging, construction, and display use. Our materials meet strict standards for durability, clarity, and safety. Whether you need something flexible or rigid, we have options that fit your product goals. We also support customization for size, color, and performance. Let’s look at two of our most trusted materials.

These PS sheets offer a clean, polished surface and strong visual appeal. They are lightweight, easy to shape, and suitable for various creative and structural applications. We provide a wide range of sizes and colors, ready to match different market needs.

![High Transparency PS sheets Polystyrene Sheet High Transparency PS sheets Polystyrene Sheet]()

Product Parameters:

| Specification | Details |

| Density | 1.05 g/cm³ |

| Thickness | 0.8–12 mm |

| Available Colors | Clear, opal, red, blue, yellow, frosted, tinted |

| Standard Sizes | 1220×2440 mm, 1220×1830 mm |

| Key Applications | Doors, signage, covers, photo frames |

Key Features:

High transparency and gloss

Strong impact and crack resistance

Good UV and weather durability

Non-toxic, safe for indoor use

Easy to fabricate and print

You’ll find these sheets used in advertising boards, display panels, safety shields, and home decoration parts. They work well in areas where clarity and toughness matter.

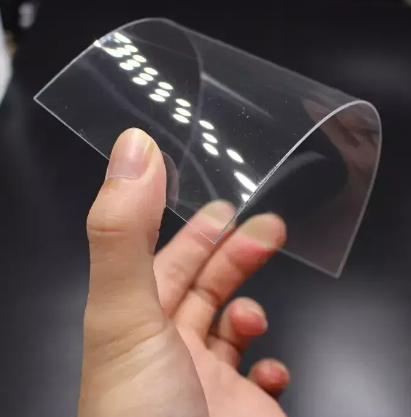

Transparent PVC Sheet from HSQY

Our transparent PVC sheets are ideal when both appearance and product protection are needed. They’re lightweight but strong enough to resist bending, scratches, and moisture. Brands use them in window boxes, folding cartons, and retail displays.

![the transparent PVC sheet the transparent PVC sheet]()

Product Parameters:

| Specification | Details |

| Thickness | 125–300 microns |

| Standard Sizes | 700×1000 mm, 1220×2440 mm |

| Custom Sizes | Available upon request |

| Key Applications | Packaging for electronics, cosmetics, food |

Key Features:

Great product visibility for packaging

Barrier against water, dust, and damage

Printable surface for branding

Easy to shape and seal

Fits window boxes and folding packs

We support bulk orders with fast lead times. Our team handles custom shapes, die-cut services, and special treatments like anti-static coating.

As the largest polystyrene sheet manufacturer in East China, we run three dedicated factories and nine distribution hubs. This means stable supply, consistent quality, and responsive service.

How to Choose Between PS and PVC Sheets

If you're trying to decide between PS and PVC sheets, start by thinking about what your product really needs. Some projects require strength and durability. Others just need something that looks clear and clean for display. Ask yourself these questions to narrow it down.

Do I need strength or clarity?

Is the item disposable or meant to last?

Will it face heat, chemicals, or UV exposure?

Am I using transparent plastic for packaging or display?

PVC is stronger, more flexible, and better at handling rough treatment. It's often used for things like cladding, pipes, or packaging that needs to resist water, dust, or outdoor conditions. If you want a longer-lasting solution, it’s the better fit.

PS, on the other hand, is light, clear, and perfect for short-term packaging or promotional items. You’ll often see it used in bakery boxes, retail windows, and creative displays. It's easy to mold and gives sharp edges and smooth finishes.

Here’s a quick guide to help you compare:

| Property | PVC Sheet | PS Sheet |

| Strength | Higher | Lower |

| Clarity | Good | Excellent |

| Flexibility | Moderate | Rigid |

| Heat Tolerance | Moderate (CPVC is better) | Low, starts to deform earlier |

| Best Use | Durable packaging, construction | Visual display, disposable trays |

| UV Resistance | Low | Low |

| Ideal for | Long-term use | Light-use packaging |

| Transparent packaging use | Yes | Yes |

So if the goal is protection, pick PVC. If it's more about presentation, PS might be the smarter choice.

Conclusion

PVC and PS plastic each have clear strengths. PVC is better for strength, moisture resistance, and long-term use. PS works well when light weight and clarity matter most. It's great for packaging or displays. When choosing between them, think about durability, exposure, and purpose. HSQY PLASTIC GROUP offers trusted PS and PVC sheet solutions for many industries.

FAQs

What is the main difference between PVC and PS plastic?

PVC is more durable and flexible. PS is lighter, clearer, but more brittle.

Can both PVC and PS sheets be used for packaging?

Yes. PS is great for display clarity. PVC offers better protection and sealing.

Which material is more heat-resistant?

CPVC, a type of PVC, handles heat better. PS melts at higher temps but deforms early.

Is PS or PVC more eco-friendly?

Both are recyclable. But PS foam often ends up in landfills or oceans. PVC recycling is improving.

What products does HSQY offer in PS and PVC sheets?

HSQY provides high transparency PS sheets and clear PVC sheets for packaging, signage, and construction.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu