Have you ever wondered how clear polycarbonate sheets really are? These versatile materials are gaining popularity across various industries.

In this article, we’ll explore the definition and composition of polycarbonate sheets. You’ll learn about their transparency and the many applications they serve.

What Are Polycarbonate Sheets?

Definition and Composition

Polycarbonate sheets are a type of thermoplastic. They are made from a polymer known as bisphenol A (BPA). This material is known for its unique properties.

Key Properties:

● Lightweight: Polycarbonate sheets are significantly lighter than glass, making them easier to handle and install.

● Durable: They resist impact and weathering, ensuring longevity in various applications.

● Impact-Resistant: These sheets can withstand heavy blows, making them ideal for safety and security uses.

Types of Polycarbonate Sheets

There are several types of polycarbonate sheets available. Each type serves different purposes and offers unique benefits.

1. Clear Polycarbonate Sheets

a. These are the most common type. They allow up to 88% light transmission, similar to glass.

b. Ideal for applications where visibility is crucial, such as windows and skylights.

2. Frosted and Tinted Options

a. Frosted sheets provide privacy while still allowing light to pass through.

b. Tinted sheets come in various colors, reducing glare and UV exposure.

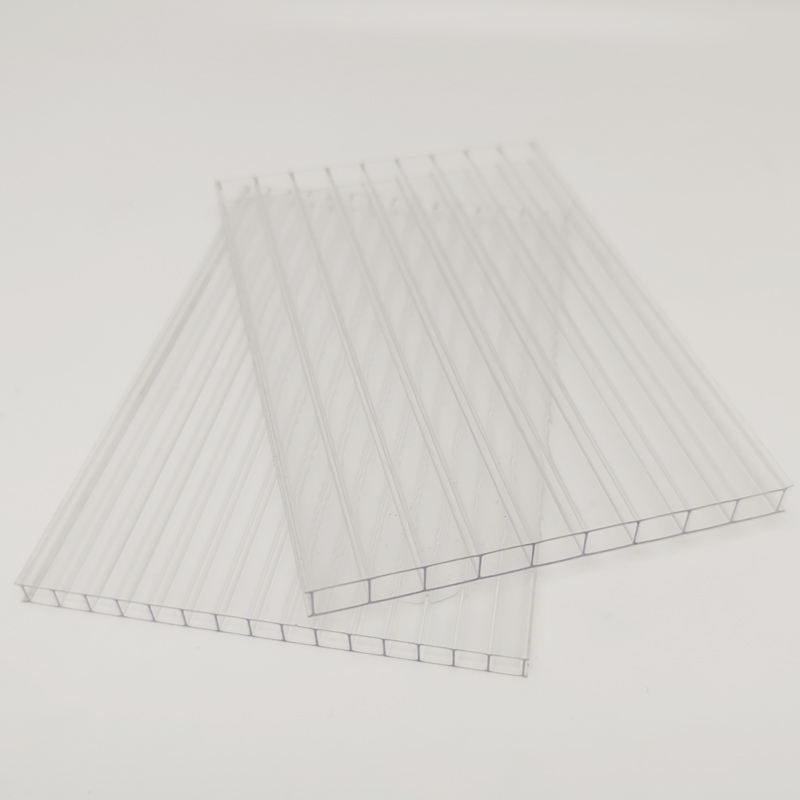

3. Multiwall Polycarbonate Sheets

a. These sheets have multiple layers, offering excellent insulation.

b. They are commonly used in greenhouses, where temperature control is essential.

Type | Light Transmission | Common Uses |

Clear Polycarbonate | Up to 88% | Windows, skylights |

Frosted Polycarbonate | Moderate | Privacy screens |

Tinted Polycarbonate | Variable | Signage, UV protection |

Multiwall Polycarbonate | High | Greenhouses, roofing |

Polycarbonate sheets are versatile and can be used in many settings. From construction to automotive, their applications are vast.

Can You See Through Polycarbonate Sheets?

Transparency Levels

When it comes to clarity, polycarbonate sheets hold their own against glass. They offer impressive transparency, making them suitable for various applications.

Comparison of Clarity:

● Polycarbonate: Light transmission can reach up to 88% for clear sheets.

● Glass: Typically, glass also provides high clarity, but it is heavier and more fragile.

Material | Light Transmission | Weight | Impact Resistance |

Polycarbonate | Up to 88% | Lightweight | High |

Glass | High | Heavy | Lower |

Factors Affecting Transparency

Several factors influence how well you can see through polycarbonate sheets. Understanding these can help in choosing the right type for your needs.

1. Thickness of the Sheet

a. Thicker sheets may reduce light transmission slightly.

b. For optimal clarity, choosing the right thickness is crucial.

2. Surface Treatments

a. Many polycarbonate sheets come with anti-scratch coatings.

b. These treatments enhance durability and maintain transparency over time.

3. Color and Tint Options

a. Tinted sheets can reduce glare but may also limit visibility.

b. Frosted options provide privacy while still allowing light to filter through.

Key Points:

● Clear polycarbonate sheets are highly transparent.

● Thickness, treatments, and color choices all affect visibility.

In applications where visibility matters, understanding these factors is essential for making an informed choice.

Common Uses of Polycarbonate Sheets

Construction Industry

Polycarbonate sheets are widely used in the construction industry. They serve various purposes, thanks to their unique properties.

● Glazing Applications:

○ Frequently used for windows, skylights, and curtain walls.

○ Their high light transmittance allows natural light to flood into buildings.

● Architectural Benefits:

○ They enable innovative designs in large-scale commercial structures.

○ Available in different thicknesses and colors, they meet both aesthetic and functional needs.

● Roofing and Cladding:

○ Commonly utilized for roofing and cladding in industrial buildings.

○ Their impact resistance and weather durability make them ideal for harsh environments.

Feature | Benefit |

High Light Transmittance | Bright interiors |

Weather Durability | Long-lasting performance |

Custom Thickness and Color | Tailored to design requirements |

Automotive Industry

In the automotive sector, polycarbonate sheets play a crucial role. They enhance both safety and performance.

● Exterior Components:

○ Used in headlight lenses and body panels.

○ Optical clarity and heat resistance are vital for these applications.

● Lightweighting:

○ Contributes to vehicle lightweighting, improving fuel efficiency.

● Interior Components:

○ Found in dashboards and door panels.

○ They offer good dimensional stability for proper fitting.

Key Points:

● Polycarbonate helps reduce vehicle weight.

● It maintains clarity and resists heat.

Agricultural Industry

Polycarbonate sheets are also essential in agriculture. They provide benefits for both plants and livestock.

● Greenhouses and Nurseries:

○ Excellent insulation properties and UV protection for plants.

○ Special coatings prevent condensation, promoting optimal growth.

● Livestock Housing:

○ Create bright environments for animals.

○ Their impact resistance withstands livestock movement.

Application | Benefits |

Greenhouses | UV protection, insulation |

Livestock Housing | Bright environments, impact resistance |

Safety and Security Applications

Polycarbonate sheets are vital for safety and security. Their properties make them suitable for various protective uses.

● Security Barriers:

○ Used in prisons, banks, and high-security facilities.

○ High impact resistance ensures protection while maintaining visibility.

● Protective Shields:

○ Lightweight and transparent, ideal for face shields and machine guards.

Important Features:

● Clear visibility enhances security.

● They are durable and reliable.

Advertising and Signage

In advertising, polycarbonate sheets shine. Their versatility allows for creative designs.

● Signage and Display Panels:Weather resistance makes them perfect for outdoor use.

○ They can be printed on and formed into various shapes.

Advantages:

● Flexibility in design.

● Durable against the elements.

Polycarbonate sheets truly excel across multiple industries, showcasing their versatility and functionality.

Polycarbonate vs. Acrylic Sheets

When considering materials for various projects, polycarbonate and acrylic sheets are two popular choices. Each has unique properties that make them suitable for different applications.

Comparison of Properties

Let’s dive into how these two materials stack up against each other.

● Transparency and Light Transmission:

○ Both materials are transparent, but polycarbonate typically offers slightly higher light transmission.

○ Polycarbonate can transmit up to 88% of light, while acrylic ranges around 92%.

● Impact Resistance and Durability:

○ Polycarbonate is known for its exceptional impact resistance, making it nearly unbreakable.

○ Acrylic, while durable, is more prone to cracking under heavy impact.

● Weight and Ease of Installation:

○ Polycarbonate sheets are lightweight, which simplifies handling and installation.

○ Acrylic is also light, but polycarbonate often wins in larger applications due to its strength-to-weight ratio.

Property | Polycarbonate | Acrylic |

Light Transmission | Up to 88% | Up to 92% |

Impact Resistance | High (unbreakable) | Moderate (can crack) |

Weight | Lightweight | Lightweight |

When to Choose Polycarbonate Over Acrylic

There are specific scenarios where polycarbonate is the better choice.

● Specific Applications:

○ In environments requiring high impact resistance, such as security barriers or safety shields, polycarbonate excels.

○ It’s also preferred for roofing and glazing in construction due to its durability against weather conditions.

● Cost Considerations:

○ While acrylic may have a lower upfront cost, polycarbonate offers long-term savings due to its durability and lower maintenance needs.

○ Over time, investing in polycarbonate can lead to fewer replacements and repairs.

Key Considerations:

● If safety and longevity are priorities, polycarbonate is the way to go.

● For applications where clarity is paramount, both materials can work, but weigh the impact resistance carefully.

In summary, understanding the differences between polycarbonate and acrylic helps in making informed decisions for your projects.

![HSQY 4mm double wall colored polycarbonate roof sheet hollow polycarbonate sheet HSQY 4mm double wall colored polycarbonate roof sheet hollow polycarbonate sheet]()

Maintenance and Care for Polycarbonate Sheets

Keeping polycarbonate sheets in great condition is essential for their longevity and performance. Here are some tips on how to maintain them properly.

Cleaning and Maintenance Tips

To ensure your polycarbonate sheets remain clear and functional, follow these cleaning guidelines:

● Recommended Cleaning Solutions:

○ Use a mild soap solution mixed with water for regular cleaning.

○ Avoid harsh chemicals, as they can damage the surface.

● Cleaning Methods:

○ Gently wipe the sheets using a soft cloth or sponge.

○ Rinse thoroughly with clean water to remove any soap residue.

● Avoiding Abrasive Materials:

○ Never use abrasive pads or brushes; they can scratch the surface.

○ Stick to non-abrasive materials to maintain clarity.

Cleaning Tip | Recommendation |

Cleaning Solution | Mild soap and water |

Cleaning Tool | Soft cloth or sponge |

Avoid | Abrasive materials |

Longevity and Durability

Understanding what affects the lifespan of polycarbonate sheets helps in their care.

● Factors Contributing to Lifespan:

○ Proper installation plays a key role in durability.

○ Regular maintenance prevents buildup of dirt and grime.

● UV Resistance and Weathering Effects:

○ Many polycarbonate sheets come with UV protection, which helps prevent yellowing and degradation.

○ Weathering can impact performance, so consider protective coatings if exposed to extreme conditions.

Key Factors:

● UV resistance enhances longevity.

● Regular cleaning keeps sheets looking new.

By following these maintenance tips, polycarbonate sheets can provide excellent service for years, maintaining their clarity and strength.

Conclusion

Polycarbonate sheets are highly transparent and versatile. They excel in various applications, from safety barriers to roofing.

Their durability and impact resistance make them a reliable choice.

Consider using polycarbonate sheets for your next project. They offer long-lasting performance and clarity, making them an excellent investment.

FAQs About polycarbonate sheet uses

Q: Are polycarbonate sheets completely transparent?

A: Polycarbonate sheets are highly transparent, allowing up to 88% light transmission.

Q: How do polycarbonate sheets compare to glass in terms of visibility?

A: While both are clear, polycarbonate offers better impact resistance and durability than glass.

Q: What are the best applications for polycarbonate sheets?

A: They are ideal for safety barriers, roofing, glazing, and outdoor structures.

Q: Can polycarbonate sheets be tinted or frosted?

A: Yes, polycarbonate sheets can be tinted or frosted for aesthetic or privacy purposes.

Q: How do I maintain my polycarbonate sheets for longevity?

A: Clean with mild soap and water, avoiding abrasive materials to prevent scratches.

English

简体中文

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu