- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

PC sheet is short for polycarbonate sheet. Polycarbonate (PC) plastic sheets are a naturally transparent amorphous thermoplastic. Although they are made commercially available in a variety of colors (perhaps translucent and perhaps not), the raw material allows for the internal transmission of light nearly in the same capacity as glass. Polycarbonate polymers are used to produce a variety of materials and are particularly useful when impact resistance and/or transparency are a product requirement (e.g. in bullet-proof glass). PC is commonly used for plastic lenses in eyewear, in medical devices, automotive components, protective gear, greenhouses, Digital Disks (CDs, DVDs, and Blu-ray), and exterior lighting fixtures. Polycarbonate also has very good heat resistance and can be combined with flame retardant materials without significant material degradation. Polycarbonate plastics are engineering plastics in that they are typically used for more capable, robust materials such as in impact resistant “glass-like” surfaces.

The following diagram shows the relative impact strength of polycarbonate when compared to the impact strength of other commonly used plastics such as ABS, Polystyrene (PS), or Nylon.

Polycarbonate sheets (PC sheets) are those that have replaced glass and polycarbonate in various applications because of their numerous benefits today. These sheets are available in a variety of qualities and thicknesses. When compared to glass, they are much lighter in weight, yet durable, and resistant to breakage and cracks. These are only few of the reasons why polycarbonates are today so popular among the users for constructional purposes.

Earlier this material was used only in commercial structures as these sheets were very expensive to purchase. A polycarbonate sheet was seen only in high profile restaurants, cafes, lounges and offices. But with the growing realization of its benefits, people starting opting for this material more and more. This led to high demand of the material, thus lowering costs. Today, it is so affordable that it is being used in a wide range of residential constructional purposes. Polycarbonate is used for doors and windows, instead of glass. To enhance modern home decors, these sheets are also used for showers and swimming pool enclosures. Other areas where these sheets are used in residential projects include balconies, patios and decks. In the commercial sector, they are highly used in greenhouses, sports stadiums, railway stations, carports and office buildings.

It is the multiple advantages that polycarbonate has that makes it so widely used today. Some of the most important benefits are listed below.

Polycarbonates are so light weight yet durable. This makes them very easy to install. They can be easily handled and can be fixed with the help of screws and support rods, or can be easily welded. Also, these sheets can be easily cut with the help of sharp-edged scissors and circular saws without the need of any additional tools and machinery.

The light weightiness of polycarbonate makes it easier to handle, transport and carry. Therefore, the costs involved with the labour and transportation are highly cut down. This makes polycarbonates even more affordable even after purchase.

Polycarbonate, being so strong and flexible, helps the structures it is used in to be more creatively designed. Unlike glass, the structures that use polycarbonate can be shaped like domes, igloos and many other fancy shapes that add a design feature to the building.

Polycarbonates are resistant to impact and any kind of damage. Therefore, these sheets can be used in areas that are prone to stone, hail, rain, wind, storm and snow. Even in the worst case of breakage, these sheets do not produce harmful shards like glass. Also, these sheets are highly resistant to flame and do not cause toxic gases when on fire. So, they can also be conveniently used in areas prone to fire.

The ultimate property of polycarbonate to block sound makes it a popular material used in areas that require privacy like conference rooms, office cabins, etc.

One of the most beneficial features of polycarbonate is that it lets in maximum sunlight while keeping out the harmful UV radiations. Therefore, it is the ideal choice when you want maximum light to come in without being harmful. This property makes it the most widely used in greenhouses to help the plants within to grow well while keeping them protected against burning.

There are many other areas where polycarbonates are used, other than constructional purposes. They are also used in the advertising industry, for police equipment, automobile parts, DVDs, lenses and many other applications. Whatever your area of usage, you must get in touch with Tuflite Polymers to get your hands on the best quality polycarbonate sheets available in a variety of qualities, types, colours and designs.

PC sheet is used by manufacturers, business and DIYers for many different purposes.

Businesses and manufacturers make different products using polycarbonate.

For example, its high strength and light weight are valued for making CDs, DVDs, mobile phones and laptops; using polycarbonate to manufacture these products means they can be incredibly light yet virtually impossible to break.

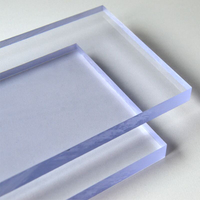

Polycarbonates excellent transparency with UV filter and durability are valuable for making shatter-proof glazing and eye glasses: polycarbonate enables lens to be thinner than if they were made from glass.

Polycarbonate is an excellent choice for applications where sheet metal lacks viability, namely when transparency is needed and when a non- conductive material with good electrical insulation is a requirement.

Polycarbonate makes an excellent material for tackling DIY jobs such as secure glazing and replacing greenhouse glass to make greenhouses virtually unbreakable year after year.

Polycarbonates (PC sheets) require very high processing temperatures, which makes it a little costlier to manufacture the material. Polycarbonates are generally not scratch resistant. So, even though they won't break with even the strongest impact, they may scratch.

Polycarbonate (PC sheet) is a relatively easy surface to bond. Surface preparation for bonding polycarbonate with Industrial adhesive is possible. Generally, it doesn't require any surface preparation and can be bonded “As Received”.

6. Is the PC sheet okay for food applications?

With good heat resistance, close gauge tolerance, and high impact strength, FDA approved polycarbonate sheet is ideal for food applications such as commercial serving bowls, candy molds, hospital trays, incubators, and more.

7. Do PC sheets have any wear resistance?

Scratch-resistant polycarbonate features a proprietary coating on both sides that significantly improves the plastic sheet's resistance to weathering, ultraviolet damage, chemicals, acids, and so much more.

Properties of PC sheets: abrasion and chemical resistance.

8. What are the unique characteristics of PC sheets?

PC sheets are resistant to mineral acids, many organic acids, oxidizing and reducing agents, neutral and acid salt solutions, many greases, waxes and oils, saturated, aliphatic, and cycloaliphatic hydrocarbons and alcohols, with the exception of methyl alcohol.